OK so this is a project that still going, but I wanted to share some of the pictures to get an idea what is involved running AC air duct to the cockpit on a 2000 2800 SCR

I found some old pictures I took when I bought the boat. You can see the water mark on the AFT area. ( I wanted to show the AFT closet “Port Side” where the main work its going to be happening)

After the wall is removed in the AFT closet area you are going to see this ( Air Duct and the drainpipe from the cockpit (Sorry I do not know how to rotate the pictures )

Next picture the upper wook was set back (do not forget to tight all the cables . we do not want cables moving and shafting

You Also are going to find a lot of the nasty mold so be ready to clean as much as you can, Tylex mold removed worked like champ

After I did all the connection on the ‘T” I bought for the air duct. Here what it looks like on the closet area. Original AFT air duct still the same way I just used some new duct tape to reattach it to the air Aft vent

![Click image for larger version

Name: 20180325_161324[1].jpg

Views: 4

Size: 127.3 KB

ID: 5394](https://www.maxumownersclub.com/forums/attachment.php?attachmentid=5394&thumb=1&d=1523299119)

ON the piece of wood I have to drill a 4” hole and add a air ductpiece to attach the other end of the air duct going to the vent on the cockpit

Here is the other end of the air duct going to the cockpit I ran the power cable for the electric fan (red & black) to the fan that is it at the bottom of the electric panel ) I set it up there for “easy” access in case there is problem with the electric fan in the future .and Also did not want to have the FAN running close to the AFT area in case somebody is sleeping while the FAN is running. Trying to keep the noise level at the sleeping area as low as possible

This is the air duct going to the Cockpit Vent

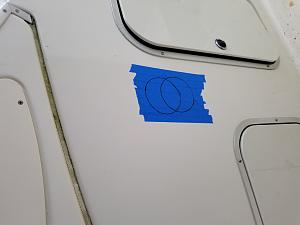

I also had to get a couple of shot of tequila , beer & what ever was available to get the courage to make a 4 inches hole on my new to me Boat. What a nightmare .. TIP… “ use a bigger tool than 4 “ maybe a 4 1/8” or even an 4 1/4 “ I did not used and It was a nightmare to get the air duct attached to the air vent at the cockpit . You need to attached the air duct right .. Do not forget :=)

Also you will need to secure the cable that are going to the switch , There is a screw that you could use instead of making another hole .. I had enough with the big hole I made to the boat already … here is the screw I am talking about ( this screw is part of the cabinet in the cockpit)

I had to secure the cable while I was working on the running air duct and cables to the fan and AFT area.. It worked since just fine I was like Batman…. I worked alone :P

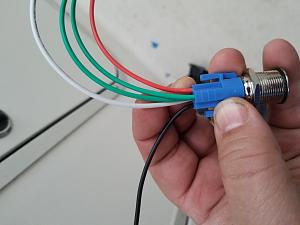

Here is the switch I used and the how is connected in order to get the light of the switch on only when the Cockpit FAN is on . Do not forget to fuse protect the power to the FAN.. That is another part of the project that I have to put the pictures together since I am redoing the electric distribution on my boat adding a third dedicated bank (two deep cycle parallel Group 31 Batteries in parallel just for the House) so each engine has it owns cranking battery . Do not want any lights or accessories running my engine batteries low. Thats another project that I am doing in parallel.

Take care Marcucho